By Jason Kelly

This content originated from Same Sky’s blog. The original version of this blog can also be viewed here.

In This Post

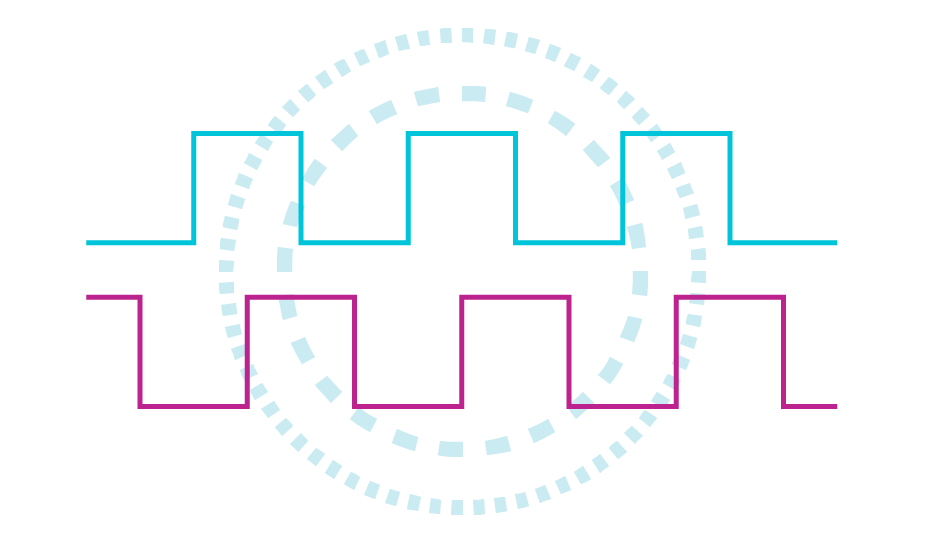

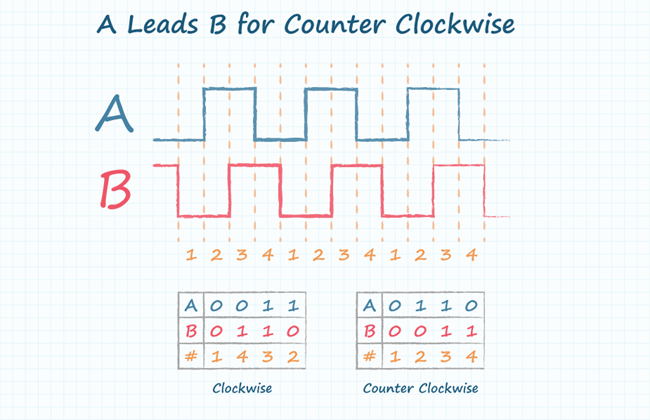

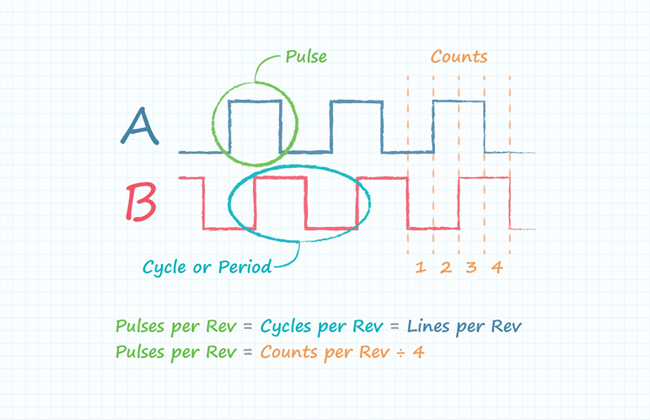

As an incremental encoder rotates it produces two square wave outputs A and B; together these signals create an incremental encoder’s quadrature output. For most encoders these square waves A and B are 90 degrees out of phase. By observing the changing states of the A and B outputs the encoder’s direction can be determined.

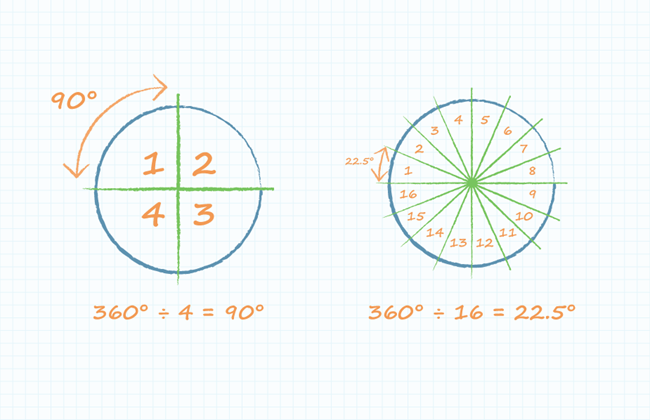

However, to determine the distance an encoder has traveled, or at what speed it is rotating, more information is required. To calculate this information it is important to know the encoder’s resolution. Resolution can be thought of as the encoder’s granularity, or put simply, how many pieces of the pie the encoder is divided into for one revolution.

Pulses Per Revolution (PPR)

Same Sky Devices uses the term PPR, or Pulses per Revolution, to represent encoder resolution. PPR describes the number of high pulses an encoder will have on either of its square wave outputs A or B over a single revolution. While Same Sky does not use PPR to represent Periods per Revolution, it would still technically be accurate as the duty cycle of our standard offering of incremental encoders is 50%. Once resolution is known it can be used to calculate how many mechanical degrees each pulse and period is equal to.

With that being said, the term PPR is not ubiquitous throughout the motion control industry. Although Same Sky uses PPR for all of our encoder products, many companies will often use the terms PPR, CPR, LPR or resolution interchangeably with conflicting definitions.

Counts Per Revolution (CPR)

CPR most commonly stands for Counts per Revolution, and refers to the number of quadrature decoded states that exist between the two outputs A and B. With both outputs A and B switching between high and low, there exists 2 bits of information represented as 4 distinct states. The term quadrature decoding describes the method of using both outputs A and B together to count each state change. This results in 4 times the amount of counts that exist for each pulse or period. Therefore, the CPR of an encoder is the encoder’s PPR multiplied by 4. It should also be noted that some encoder manufacturers use the CPR acronym to mean Cycles per Revolution. Cycles per Revolution refers to the full electrical cycles or periods on any one of the encoder outputs and is equivalent to Pulses per Revolution. With both Counts per Revolution and Cycles per Revolution using the same CPR acronym, but differing by a factor of 4, this can understandably cause some confusion and one must be careful to understand how the resolution is being defined.

Lines Per Revolution (LPR)

LPR, or Lines per Revolution, is another term that is equivalent to PPR. The line refers to the bars etched or printed onto an optical encoder’s disk. Each line on an optical encoder disk would represent a low pulse on the output as they have a one-to-one relationship.

Because resolution is defined differently across the industry, it is important to get the numbers into the same format when comparing products from different encoder manufacturers. This is best done by viewing waveforms or timing diagrams on the datasheet and if possible calculating the pulse width in degrees or arcminutes.